产能:

各工厂/车间产能缺口是多少?

哪些工序有产能富余?

物料:

需要备多少物料,物料缺口有多少?

是否可用替代物料?

计划所需数据往往分散在不同的地方

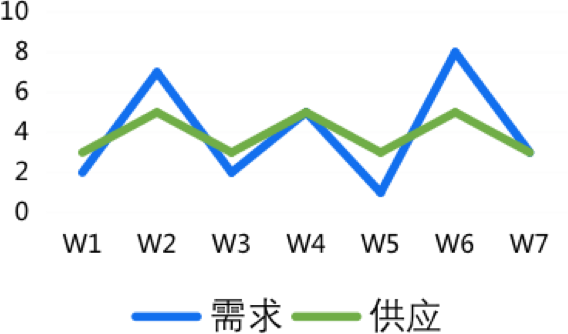

跨部门之间信息共享困难,难以对供需平衡达成一致意见

供应链可视化能力弱,决策层难以快速掌握需求、供应、 产能的整体情况

供应链路复杂

上下游供应节点众多

难以平衡各节点的需求和供应

需求只能从成品端到原料端层层传递

对于产能利用、库存水平、服务水平、成本等多目标多约束的主计划需求,传统的方式难以兼顾

供应链计划的指标可能存在冲突

难以分析每个指标对主计划的影响

难以尝试对不同指标权重的调整

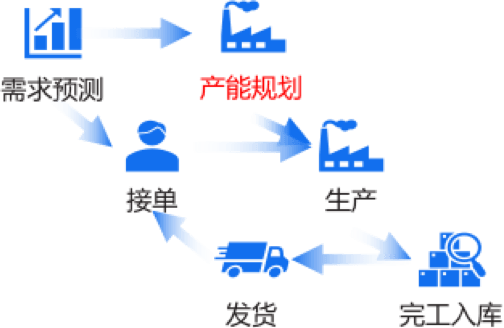

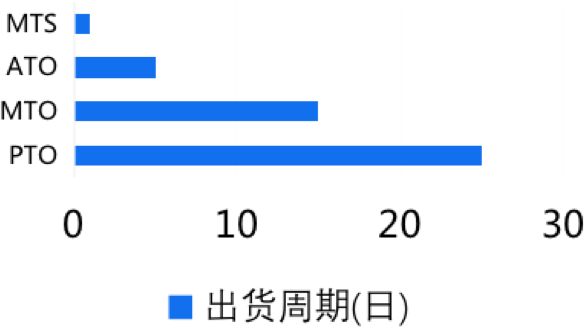

提前备产,平衡各需求供应量

让有限的产能满足最重要的客户需求!

可控呆滞风险下的提前备料

缩短出货周期,提升市场竞争力!

可控成本下的提前生产

削峰填谷,稳定生产,降低成本!

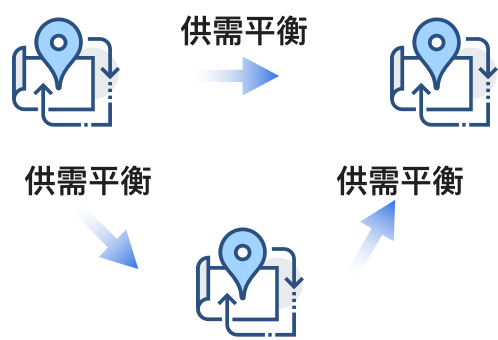

加强供应链协同

使供应链各节点按一致的目标行动!

构建包含企业全供应链各节点的完整模型,考虑各节点供应能力限制,实现整个链路的供需平衡

1实现考虑需求、产能、物料等多约束多优化目标的全局优化主计划计算

2能够模拟不同优化目标权重,不同计划策略下的计划输出,基于数据驱动的根因分析和What If分析,避免人为主观判断

3基于实时KPI决策计划的优劣判定,避免主观经验导致的片面性

4监控主计划执行进度及需求、供应、产能等异常变化,能够及时进行异常响应与主计划调整

5实现考虑需求、产能、物料供应链全流程信息贯通,需求、供应、库存、产能、计划信息可视化 ,实现端到端供应的协同工作

6产品与关键部件供应计划

关键物料需求计划

产能分配计划

库存水平趋势预测

提供能力

主要优势

供应链建模

需求管理和供应管理

多目标优化

跟踪与改善

计划发布

能力调整与场景模拟

供应链建模

需求管理和供应管理

多目标优化

能力调整与场景模拟

计划发布

跟踪与改善

供应链建模