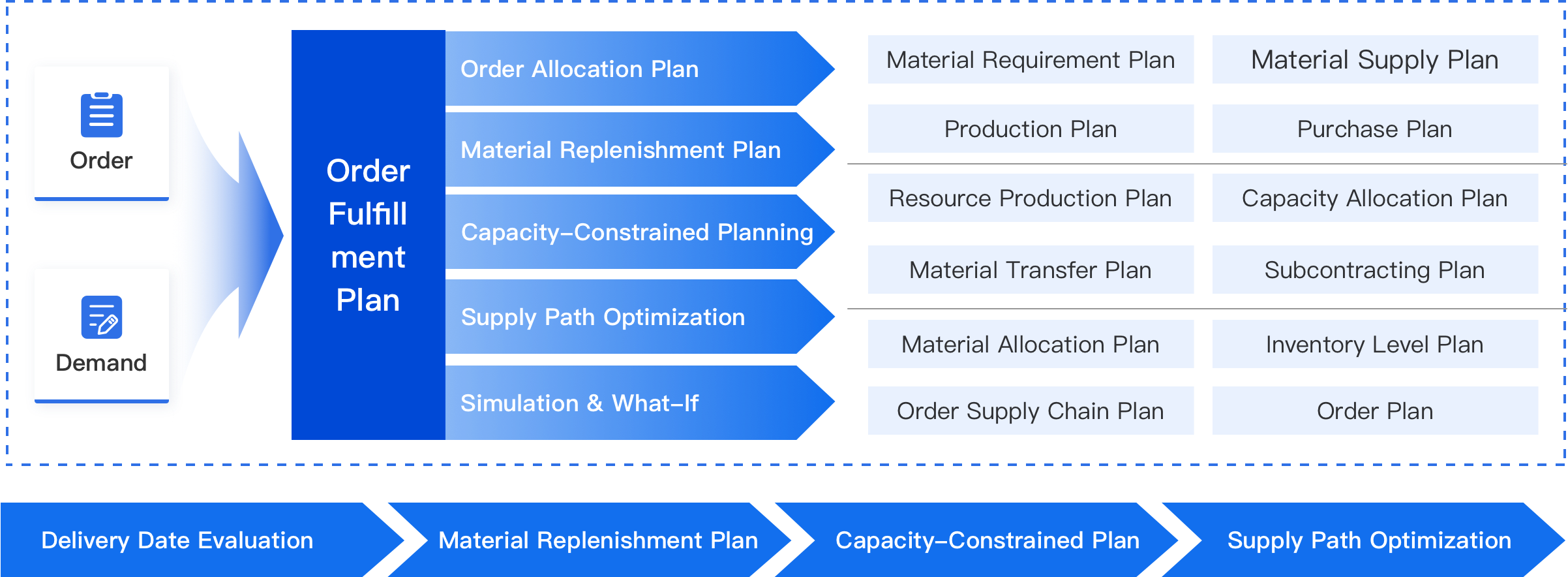

Based on the mutual constraints between production capacity and materials, it provides a material plan that matches in quantity and time.

A material plan that can allocate limited material supply to the most prioritized demands, ensuring the availability of materials for complete order production under conditions such as balancing safety stock and reducing inventory costs, as well as balancing supply and demand.

A collaborative material planning that can balance the supply and demand time and quantity of raw materials, work in progress, and finished products to achieve upstream and downstream balance.

After receiving an order, the enterprise assesses the supply capacity of each SKU and product, estimates the expected shipment date of the order, and evaluates the quota delivery date to fulfill the order delivery date commitment.

Based on order requirements, comprehensively consider multi-factory production resources, upstream and downstream collaborative resources, material inventory and demand resources, reasonably arrange the optimal production path within limited capacity, pay attention to production execution status, assess the impact of anomalies based on production anomalies, provide anomaly handling measures, and continuously optimize the supply chain production path.

Fully consider the constraints of materials and production capacity to develop a truly executable plan.

Users can use the same data to create multiple scenarios (Scenario), set different planning rules for each, compare the pros and cons of the results output by different planning rules; they can also make fine adjustments to equipment capacity, supply, demand, etc., to understand the impact of these adjustments on overall optimization performance.

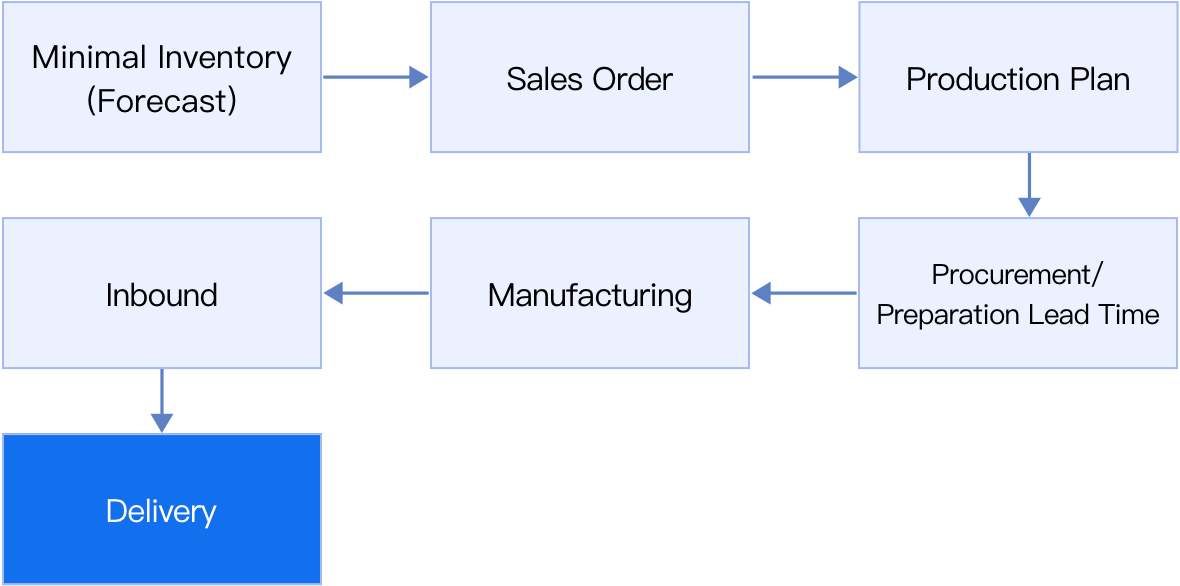

For assembled products, their production cycle is short and they are susceptible to inventory levels and supply chain fluctuations. This product helps enterprises effectively plan assembly schedules, optimize assembly processes, thereby avoiding inventory overstock, shortening delivery times, and quickly responding to customer needs.

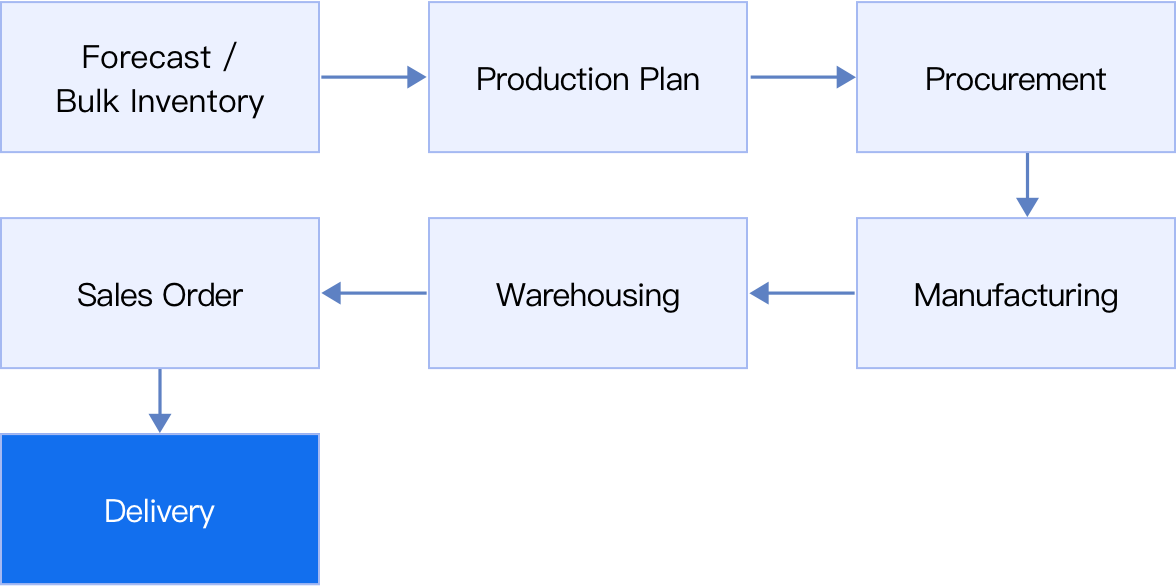

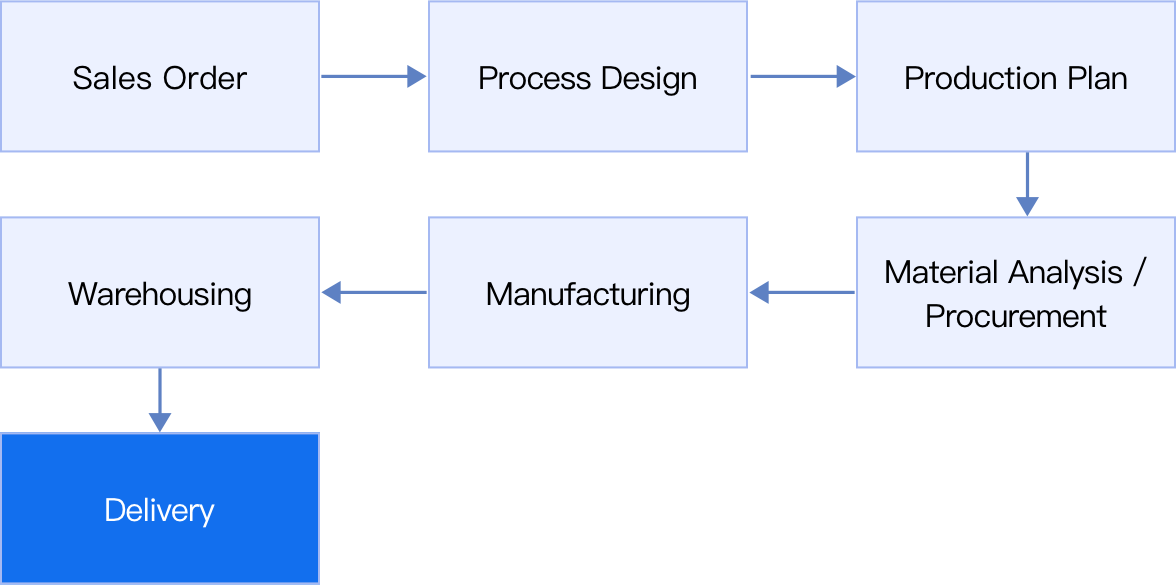

It is oriented towards the production of standardized products, helping enterprises to reasonably arrange production batches to achieve scale effects; optimizing inventory structure to ensure that popular products always have sufficient inventory and reduce the risk of production interruption caused by sudden changes in demand.

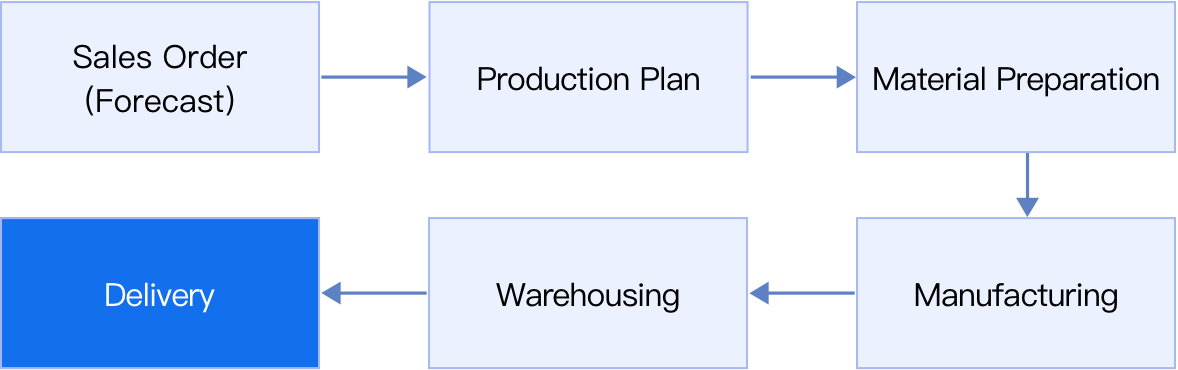

Based on order production, this product can flexibly adjust the production plan according to customer needs, precisely control the production process, and more accurately predict and meet customer needs to adapt to a market environment with diverse product types and frequent fluctuations.

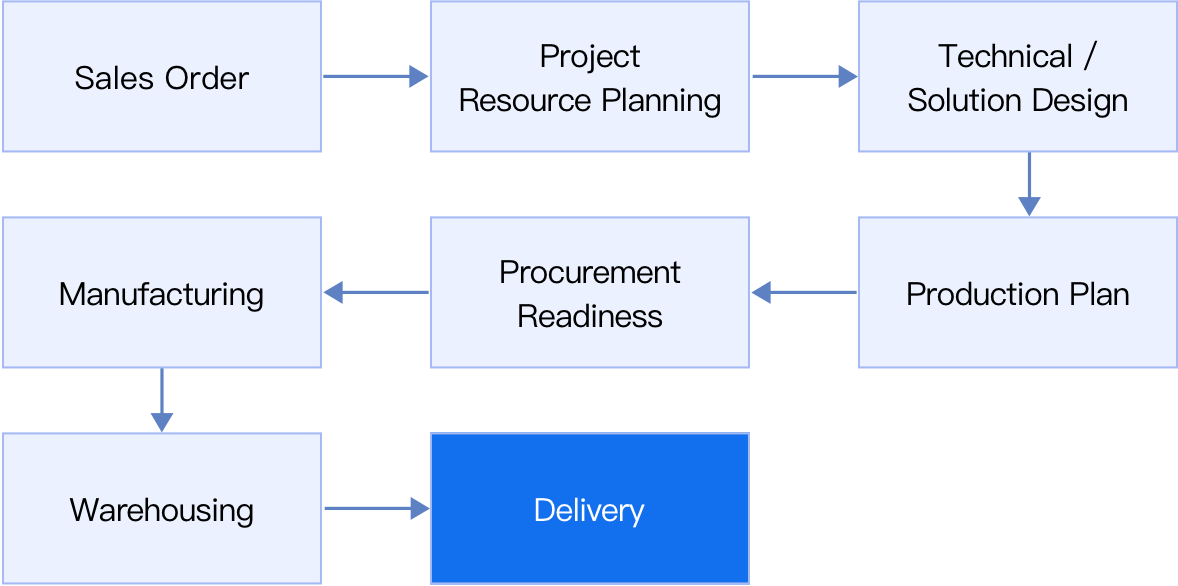

To ensure the timely delivery of customized products, the order delivery plan runs through every link from design to production, helping enterprises track project progress and coordinate quota allocation.

Through pre-set configuration templates and automated production lines, it helps enterprises optimize the configuration process, reduce configuration errors and delays, and achieve rapid configuration and delivery.

Build an intelligent supply chain planning system to achieve production linkage among monthly, weekly, and daily plans, improve production scheduling efficiency and production flexibility, display planning results on a visual interface, support manual rapid adjustment of operation plans, and optimize changeover efficiency and material anti-mistake and anti-error measures.