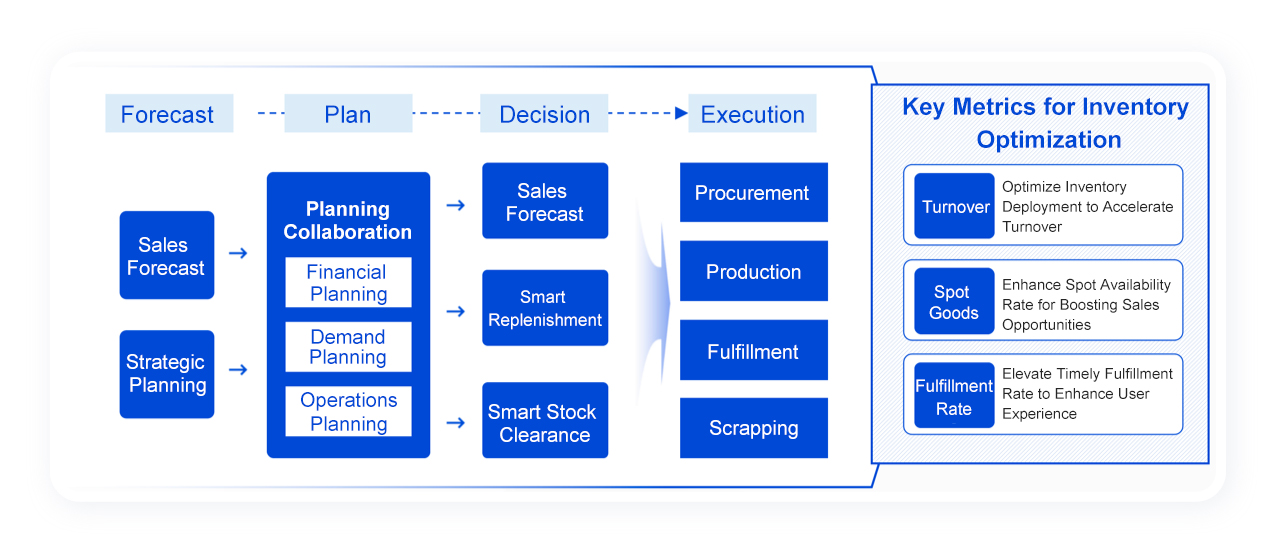

Automatically calculate the replenishment time for stores in the future period based on the Deloris algorithm platform, reducing the repetitive work of store liquidation and replenishment.

Automatically generate replenishment suggestions based on historical sales, inventory turnover, and other data to reduce inventory overstock or shortages

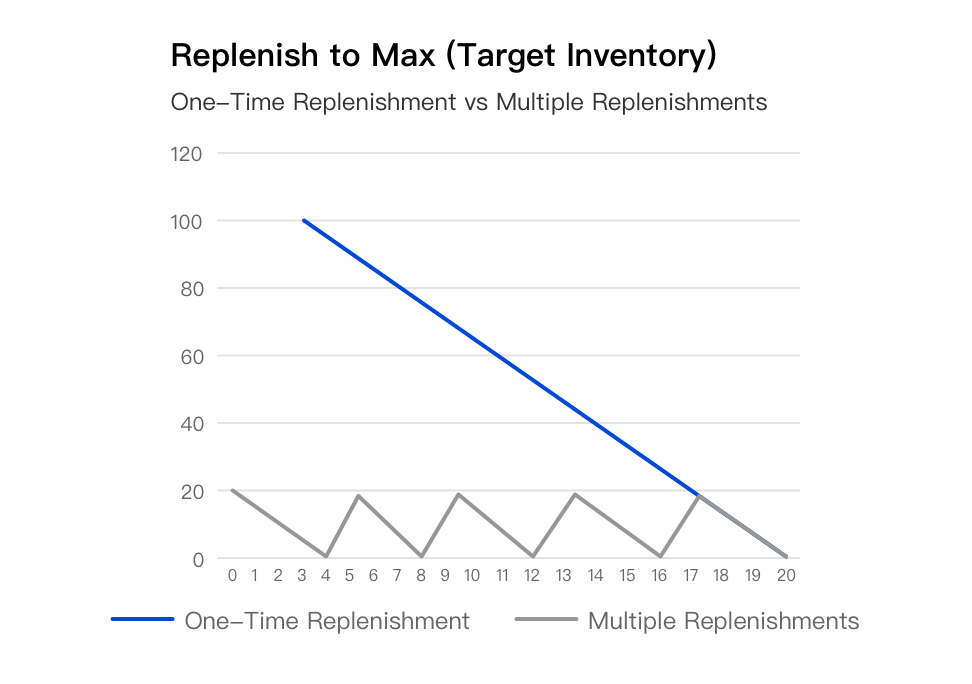

Meet the consumption needs of stores with lower inventory and reduce the inventory turnover days of goods

Reduce the out-of-stock rate of stores, lower the proportion of stockouts, and shorten the replenishment cycle

Search for historical decisions of outstanding store managers, accumulate the experience of their decision-making, and empower decision-making in other stores

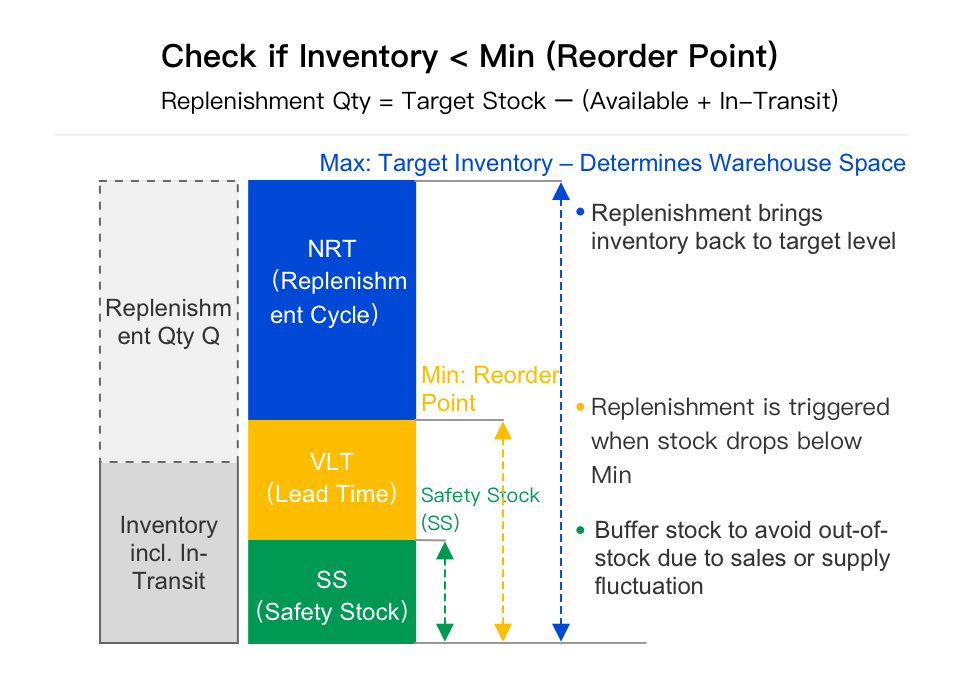

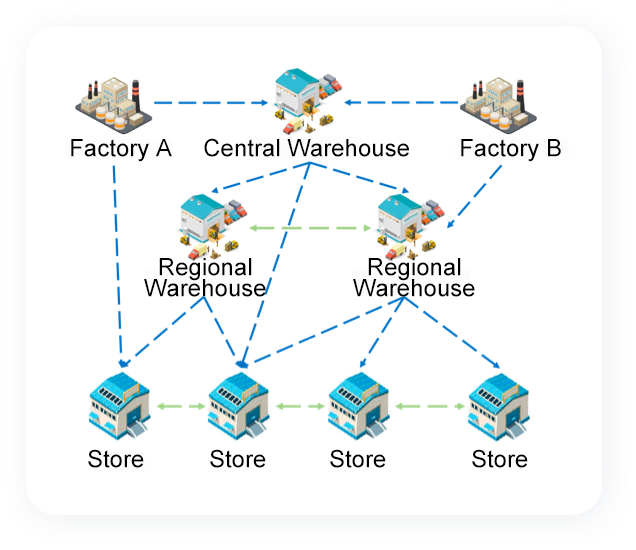

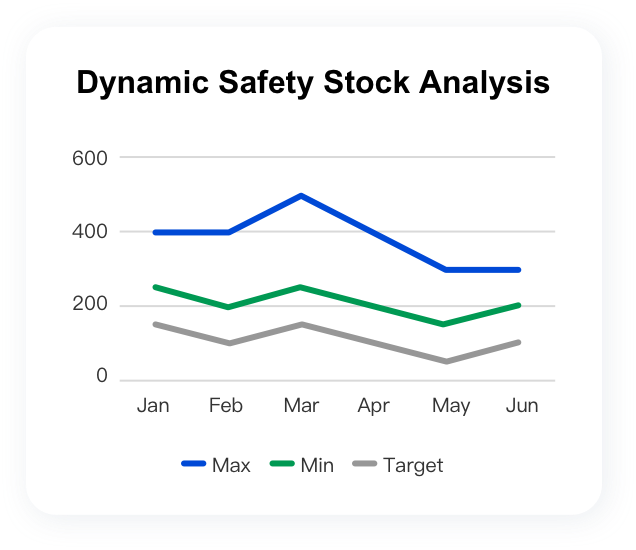

Through pre-configured inventory strategies and based on the latest demand forecasts, calculate the safety stock levels, replenishment timing, and replenishment targets for multi-level warehouses, ultimately forming executable replenishment plans and transfer plans

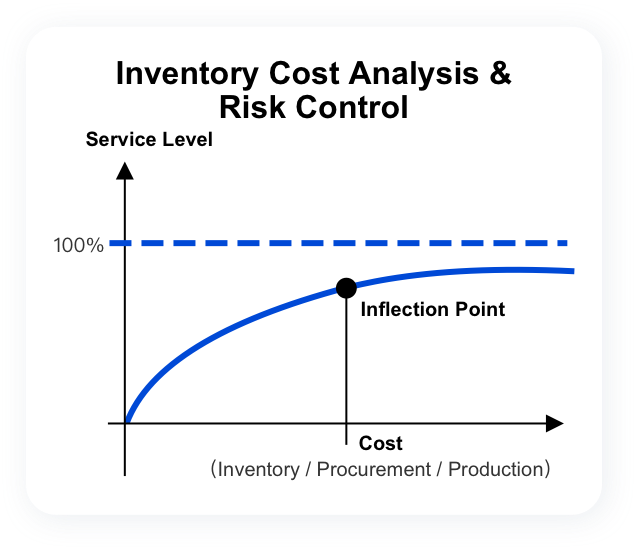

Considering the continuous fluctuations in demand and supply, establish safety stock while balancing inventory levels and store Service-level objectives to optimize inventory planning, reducing the average inventory level while keeping the supply safe and controllable.

Inventory management always revolves around business indicators such as days of inventory turnover, in-stock rate, and fulfillment rate to drive the continuous optimization and operation of the entire system, achieving the rationalization of the balance between in-stock and turnover with a profit orientation

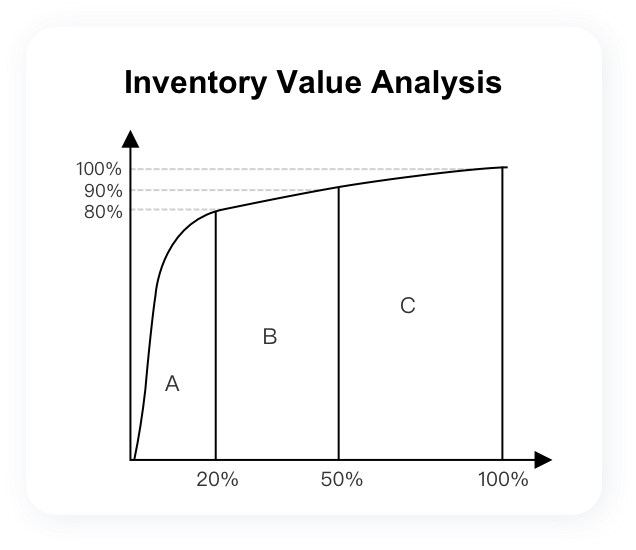

Using classical inventory theory and the newsvendor model, design an inventory optimization algorithm, comprehensively classify finished products and raw materials, and calculate indicators such as safety stock for materials to guide production and reduce inventory.